6 essential elements of a CNC machine

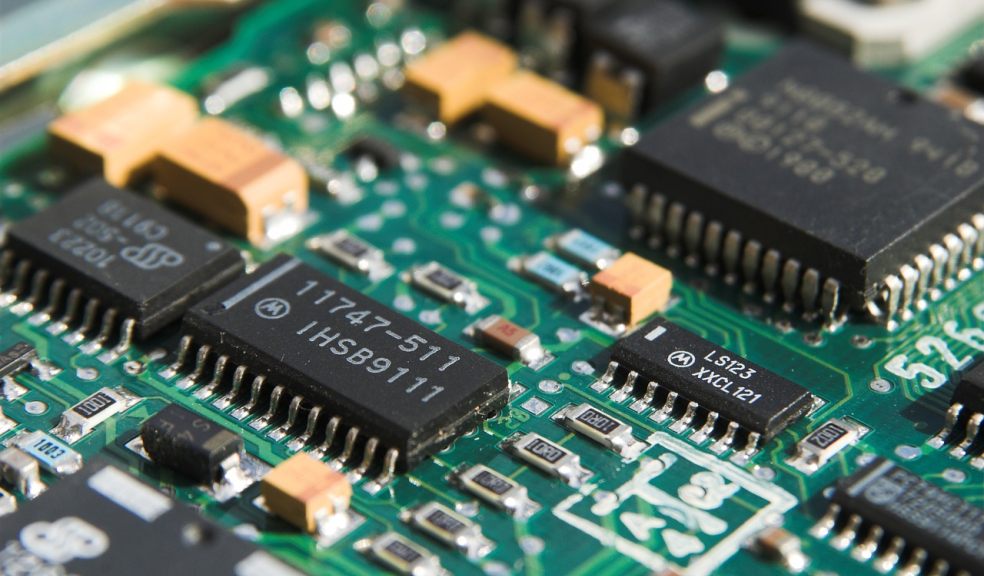

CNC (Computer Numerically Controlled) machines have made a significant contribution to the industrial industry. In simpler terms, a CNC system receives data and then interprets the same before directing specific actions. CNC systems are commonly utilized in lathes, milling machines, laser machines, sheet metal processes, and other soft automation applications. The notion was first created to control machine tool operation and movements. Finding a suitable CNC spare parts distributor is necessary part of the process.

As previously stated, the CNC is a computer-based electronic device that accepts information in digital format from input devices as well as location information for certain machine elements. The machine then interprets the digital input as needs for new machine element placements and issues appropriate direction commands. Click here to Know more.

What are the 6 essential components of a CNC machine?

Numerical control is a method of controlling numerous functionalities of a machine tool using an input signal. A CNC machine's heart and brain is a microprocessor-based system. A CNC system has the following components:

- Central processing unit (CPU)

- Input devices

- Machine control panel

- Programmable logic controller (PLC)

- Servo-control unit

- Display unit

Data is frequently transferred from the PC to a CNC machine using a serial connection connector. Serial communications are governed by international standards.

A CNC system's control is handled by the CPU. As part of the software, it receives data from the memory. After that, the data is decoded and converted into signals for position and velocity control. It regulates the spindle's or control axis' movement. If an action does not correspond to the data programmed, it is corrected. For the operation of the CNC machine axes, the speed control unit works in conjunction with the CPU.

The major benefits of CNC machines

CNC machining is widely used in the manufacturing business. Some of the benefits of CNC machining are as follows:

- Increased adaptability and consistency

- Indirect costs are lower.

- Productivity increases

- Quantity that is consistent

- Operation that is reliable

- Reduced time spent on non-productive tasks

- Increased precision

- Reduced time to market

- Material handling that is automated

The first advantage that practically all CNC machine tools provide is improved automation. Remedial action in a manufacturing process can be reduced or eliminated entirely by the producer. There are a lot of CNC units that can run unattended, allowing operators to work on other duties. Reduced operator fatigue, reduced human errors, and predictable machining time, and so on are some of the other advantages. A reputed CNC spare parts distributor will be able to provide the best parts and support in case of technical deficiency.

How can Automation Store help?

At Automation Store Ltd, they design and build custom machines to solve difficult industrial problems and provide one-of-a-kind automation solutions. For a variety of industrial applications, they also create custom mechanical hardware and software solutions. To learn more on the subject of CNC machining applications and other automation solutions and other CNC spare parts, you can contact them.