How to cut rigid foam insulation

The Foam Board is an insulated solution that is simple to manage and can improve the energy output of your home by something like as 70%. Rigid foam is also often used to carve figures, and a range of techniques for cutting foam are used by sculptors and construction workers alike.

Needed Materials and Tools

- Utility Knife

- Marker of felt tip

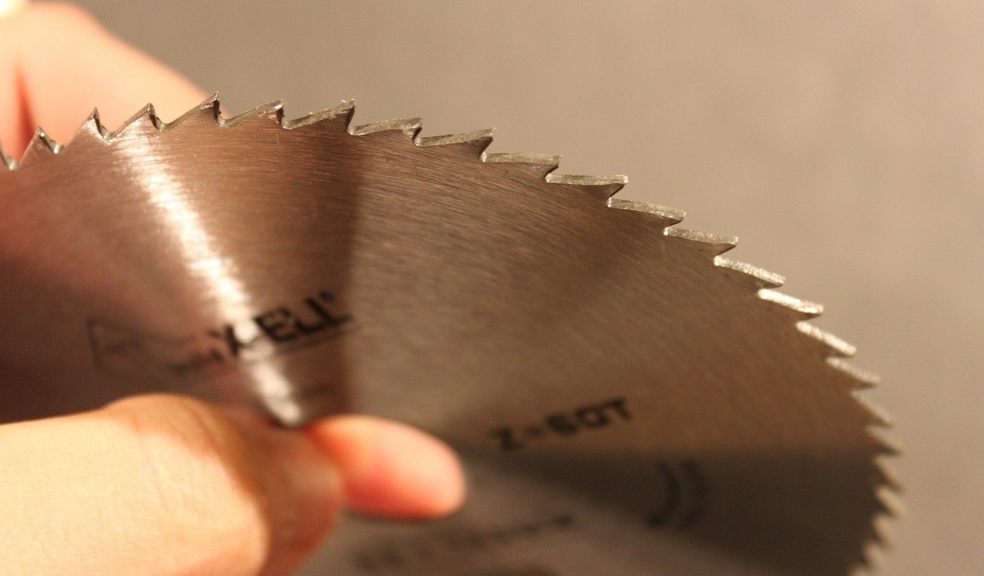

- Round Saw

- Goggles

- Metal cuts or jigsaw blades for all purposes

- Vise

- Worktable

- Grinder

- Round saw of old steel

- Jigsaw

How to Cut Rigid Foam Insulation: Step by Step

Part 1: Readying the cut

- Calculate the cut with a ruler: If you cut the rigid moisture for a particular project, you would need to estimate its length and width.

- Label with a durable marker the slicing path on the foam: Put the straightedge ruler on the solid foam insulation and utilize those as a reference when making your mark.

- Place a flat surface with the solid foam insulation: When you are cutting, keeping the board smooth will help you cut accurately. Find a flat surface for removing the insulation boards if you don't have a working bench.

- Fasten hard foam to the smooth surface: To protect the working surface on both sides, apply rubber clamps. Secure the straightening next to the cutting line to make an accurate incision.

Part 2: Utility knife cutting

- Cut the isolated foam into a segmented blade: Segmented cuts extend around the base of the blade.

- Give your utility knife the isolated foam: Place the knife on the top of the stretch and work as near as possible down the cutting surface.

- To end the incision, make a second slash: It is usually not completely removed by the grading of the isolation foam once. Run the tool knife for a second time through the thread, separating it from the rest of the isolation portion.

- Take the pin and look at the bit of foam: Should the cut look irregular or the piece is wider than needed, draw a different line, protect the piece of foam with the clamps, and cut it again.

Part 3 Use a Saw

- If you need an accurate cut, use an electrical saw instead of a knife: Though cuts are effective with the use of tool knives, a finer, safer incision is provided by the table saws.

- Put safety gear until the saw is handled: Safety glasses, lenses or facial shields will protect the eyes from flying moisture.

- Run via the indicated line with the saw blade: When using the handheld saw, keep it in your hands constantly.

- Detect mistakes in your rigid isolation: If the insulation remains too big, or the cut is irregular, use your electrical screw for the other cut.

Part 4 Testing alternative options

- To slice the foam, utilize a mastic knife: A mastic knife can act as a replacement, if you're not using a utility knife.

- Steam the knife before you slice it: The previously heated knife by a flame helps to lead to a cleaner cut.

- Take a Hot Wire knife to remove the foam: If you have to make sharp edges, hot wiring cutters can be perfect.