Engineering Bricks: How To Use Them

Are engineering bricks really the V12 engines of brick masonry? You bet. They are sturdy, virtually unbreakable, and impressively stand up to the elements. So, how and where should you use these bricks? Let’s find out together.

What Are Engineering Bricks?

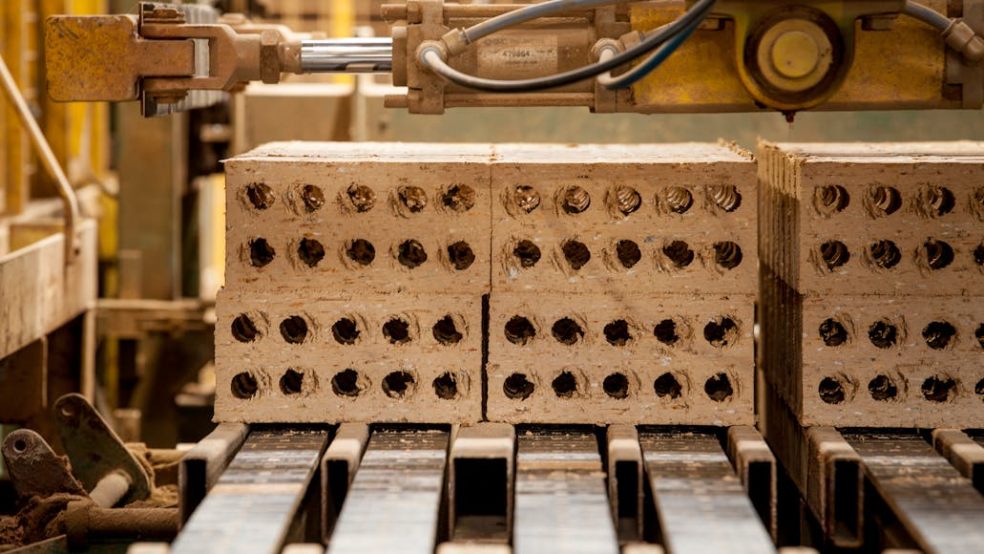

Engineering bricks are a distinct class of brick masonry built to offer extra strength and water resistance. These are the two defining qualities of this category of brick masonry, measured as compressive strength and absorption rate.

Compression strength refers to the brick’s ability to withstand pressure, meaning it shouldn’t break or crack under compression.

Absorption rate refers to the brick’s ability to draw in water. A low absorption rate is desirable because the brick will not absorb too much moisture when soaked in water for long periods. Thus, it’s less likely to suffer damage due to saturation. It also dries quickly after exposure to water, thereby minimising the risk of water damage.

To attain these properties, manufacturers use carefully chosen clay, which is much higher quality than standard brick. The clay is then fired at higher temperatures than other brick types to increase its strength and resilience.

Thanks to these enduring qualities, engineering brick is used in applications where:

- Uncompromised structural support is needed

- Strength is a priority

- Load-bearing is crucial

- Water is likely to be a problem.

So, it is the logical choice for sewer works, foundations, groundworks, tunnels, bridges and retaining walls. It’s also appropriate for constructing the lower levels of buildings.

Types of Engineering Bricks

These bricks come in two primary types: Class A and Class B.

- Class A

The stronger of the two, Class A units have a higher compressive strength—ideally higher than 125 N/mm². They also have a lower water absorption rate, at under 4.5%.

- Class B

Although not as strong as Class A bricks, they are much stronger than regular brick pieces. Their compressive strength is more than 75 N/mm², and their absorption rate is less than 7%.

How To Prevent Dampness When Using Engineering Bricks

We must remember that, even though this type of brick has a low moisture absorption rate, it’s still water-permeable. Therefore, take every measure possible to prevent moisture buildup and minimise dampness during and after construction. Here are some ways to do that:

- Include vertical and horizontal damp-proof courses.

- Vertical damp-proof courses prevent the horizontal spreading of dampness through the wall, while horizontal damp-proof courses prevent the vertical spreading of dampness from the ground up.

- Employ excellent skill when building damp-proof courses. Poor workmanship increases the likelihood of dampness.

- Use quality materials when laying the concrete.

- That means materials should meet BS standards, and you should properly gauge and use them as recommended.

- Ensure that drains and gullies are attached to the building the right way.

- Pipes and fittings attached to the building should be secured and free of all defects.

FAQs

- Why are engineering bricks expensive?

Engineering bricks are the sturdiest of all bricks. These are high-performance masonry designed with functionality in mind. Therefore, they have superior tensile and compressive strength and low porosity, moisture absorption, thermal conductivity, and creep rate. They must undergo multiple conditioning processes to bring out these desirable qualities, which pushes the production cost up. Brick size and shape also impact the cost.

- How do I check the quality of engineering bricks?

Check the indicated compressive strength and absorption rate. The compression rate should be > 125 or > 75 N/mm², while the absorption rate should be < 4.5% or < 7%, depending on class. Other physical checks include stacking the bricks to assess uniformity and see if they have cracks and thumping a pair together to test their sturdiness (they shouldn’t crack or break). Another way to test sturdiness is to stand 1.2 meters above the ground and drop the brick. It shouldn’t shatter or crack.

- Are engineering bricks longer than other bricks?

Engineering bricks have similar dimensions to other regular bricks. This similarity allows builders to combine different brick types within the same project as needed without negatively impacting the building’s stability, strength or moisture resistance.

- Can you cut engineering bricks?

Engineering bricks are quite tough and won’t budge when cut with a cold chisel. Use a power tool like the angle grinder to cut the brick. Make sure you choose one with a diamond blade, as a regular steel blade won’t penetrate the material. A diamond blade ensures greater precision and won’t damage the brick.

- Can I use engineering bricks instead of facing bricks?

While there’s nothing structurally wrong with using engineering brick units instead of facing bricks, they lack the aesthetic appeal of the latter. They are more functional than decorative, so consider this before using them for the facade. But if looks are of no consequence, you can safely use them.