Pros and Cons of CNC Laser Cutting

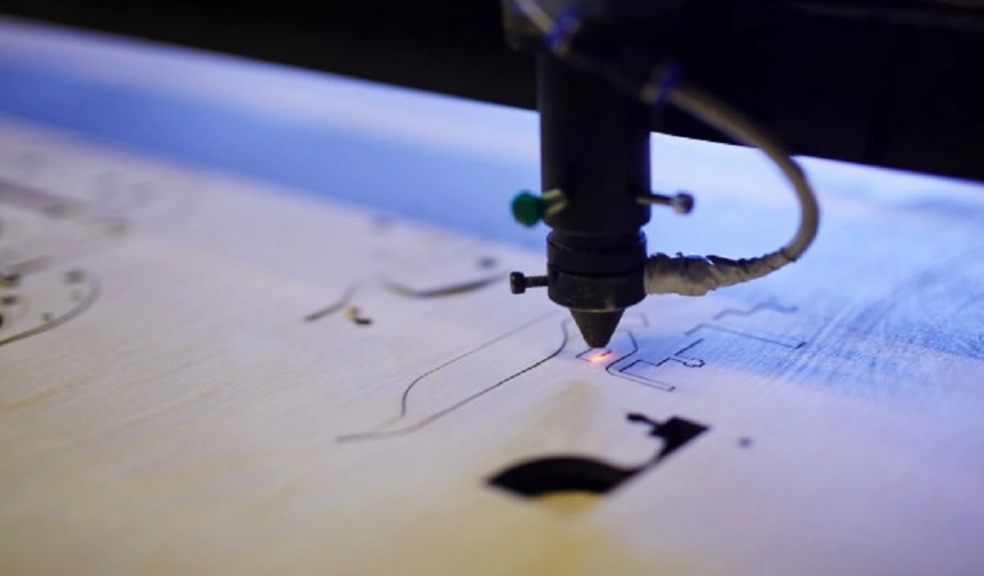

Cutting is considered one of the very basic and commonly used processes for metal fabrication. However, laser cutting is the most preferred technology that is used in multiple industry jobs as it has the upper hand over plenty of other methods.

But, simultaneously, just like everything has a flip side, so does laser cutting also has, as it has a couple of downsides attached to it.

Let us dive deeper into understanding the pros and cons of laser cutting, used majorly in manufacturing signages of different types.

Advantages of Laser Cutting

As per 1 Stop Signs, the local leaders for custom signs, banner printing, CNC cutting, and other marketing collateral in the UK, “One of the reasons engineers are inclined towards CNC laser cutting is that it comes with a huge list of benefits. The advanced laser cutting process is quite precise, flexible, cost-effective, versatile, and provides great quality, contactless cutting, and automotive possibilities.”

This is the list of advantages of laser cutting:

Flexibility

Laser cutting does not require tools for every cut. The very setup is quite suitable for cutting different shapes within the very same material with standard thickness. Also, the intricate cuts do not pose many problems. This is why laser cutting is apt for signage manufacturing as you can use your imagination to create any shape you want.

Precision

One of the biggest USPs of laser cutting is accuracy compared with the various thermal cutting methods. It provides an accuracy of almost +/-0.1, which allows the manufacturers to achieve higher precision. In most cases, a high standard reflects that there are no tolerances needed. For firms that design signage, CNC laser cutting is the automatic choice because of its accuracy.

Repeatability

+/- 0.05 mm makes sure that the parts are alike to each other.

Speed

Compared to the tractional cutting methods of mechanical cutting, laser cutting is considered quicker, especially if there is a need for complex cuts. Compared to various thermal cutting methods, such as flame or plasma cutting, lasers easily beat them in terms of speed up to a standard thickness of approximately 10 mm. The signage industry is one of the biggest users of laser cutting, as they need products to be made faster, and laser cutting helps them in their main goal.

Automation

The best part about laser cutting is that this job requires very little manpower. This is because the laser contemporary cutting machinery is quite automated. However, the role of an experienced machine operator is huge when it comes to delivering the highest quality. Factors such as the cutting speed and the need for less manual labor result in a lower cost than the various other cutting methods. Today, many machines also come with feeding systems and follow-up conveyors, but such setups require expensive laser cutting machines. All these reasons make automated laser cutting indispensable for the signage industry as it lets them create and supply large numbers of signage easily without manual effort.

Quality

Laser cutters leave very little blur, and very often, it is not even necessary to remove it. But in the end, it does depend on various factors, such as the kind of material used, the thickness, etc.

Contactless Cutting

In the case of laser cutting, it is just the beam in contact with the material; hence, there is absolutely no amount of mechanical friction that would wear the tools.

Versatility

One of the primary aspects of laser cutting, why it is used for making banner printing, custom signs, is its versatility. Laser cutting is perfect for making signage as it allows you to create any kind of design that you visualize.

Disadvantages of Laser Cutting

Although many industries, such as signage, use laser cutting to produce different parts, it still has its share of disadvantages in terms of the metal thickness, requirement of an expert, etc.

Following are the disadvantages of laser cutting:

Need of Expertise

There is a hardcore need for a specialist operator to make the most of the potential of a laser cutter. A right setup is required, as that is done by an expert who makes sure that the quality of the cutting is up to the mark.

Metal Thickness

Compared with various other thermal cutting methods, laser cutting is not very suitable for cutting thick plates. The metal fabrication manufacturers cut metals of thickness, which ranges between 15 to 20 mm, and laser cutting, in this case, is not very suitable.

Cost

The machine price of a laser cutting machine can easily reach up to £1,000,000. As compared to plasma cutters or water jets, lasers are quite costly. Although the efficiency and running costs do make it up, the initial investment in laser cutting machines is pretty high.

Dangerous Fumes

One significant advantage of laser cutting is that it is very suitable for cutting various material types. However, at the same time, the cutting method also makes the material melt, which results in dangerous fumes and emitted gases. Hence, one requires a pretty expensive ventilation system to keep up the safety of the environment.

Considering all, it is a good idea to invest in CNC laser cutting machines, as they are ideal for fast-moving industries, such as the signage industry. Starting from correx boards, window graphics, foamex boards, or roll-up banners, CNC laser cutting machines are apt for producing all of these.