Shocks, Fires, and Electrical Hazards - How to Keep Yourself Safe

Electrical hazards lurk in your home or any working environment whether one knows it or not. From plug socket covers to overheating gadgets, it is essential to spot the signs of electrical hazards before they might pose a serious risk to people working around them.

This piece of content, therefore, will walk users through everything they need to know about electrical dangers, the health risks they might cause, and preventive steps to keep everyone safe while working.

Electrical Safety & Its Importance

Electrical safety is a general term and a practice used for people whose work involves handling and maintaining electrical equipment. Electrical safety is a set of guidelines to follow to control and mitigate electrical hazards within any work type or environment. Failing to follow these guidelines or safety practices can result in serious accidents, injuries, fatalities, or near misses.

When talking about electrical hazards, the most dangerous ones include working on construction sites. This sector accounts for 52% of all electrical fatalities in US workplaces, according to the Bureau of Labor Statistics (BLS).

Half of these fatalities or incidents occurred due to direct contact with overhead powerlines, machines, or tools containing metallic objects. Most of these electricity hazards are preventable if they are properly identified, controlled, and managed on work sites. adequate work training, competence, and work experience also play key roles in minimizing the risk of danger.

Common Electrical Hazards & Tips for Safety

Identifying electrical hazards at work help raise awareness of the risk, the severity of the injury, and how they may harm the workers.

Below are some common electrical hazards and effective safety tips to prevent them:

- Electric Shock

Electrical shocks are one of the most common types of electrical hazards. Any electrically powered equipment which is subject to chemical or water spillage or shows signs of wear or tear should be used carefully to avoid any such incidents.

- Overhead Powerlines

Overhead powerlines have high voltage which can result in major burns or electrocution hazards to the workers. Employers need to conduct regular work site surveys to ensure safety at work. Proper safety barriers and signs must be installed on-site to make people aware of the dangers.

- Spark Ignition Sources

Another major electrical risk is the sources of ignition or sparkles that may result due to faulty equipment or electric circuits or damaged wiring. These issues may cause potential sparks or fires. Therefore, special care must be taken to eliminate the risk of sparks, ignition, or fires resulting due to electricity or other flammable substances/materials.

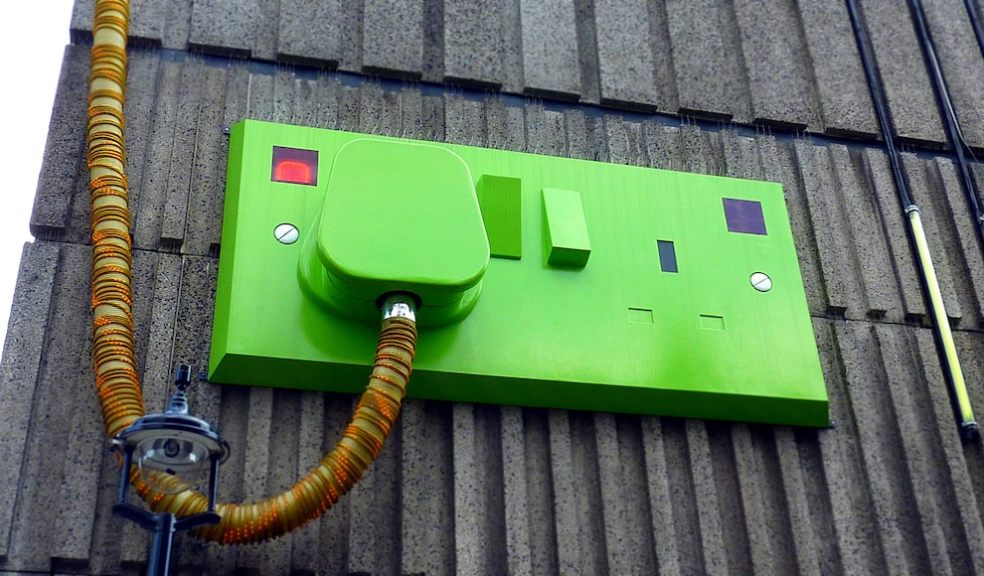

- Damaged Tools & Equipment

Exposure to damaged electrical tools or equipment can be risky. Fixing the work can pose serious health concerns unless you are qualified to do the work safely. To repair any defects, proper Lock Out Tag Out (LOTOTO) procedures must be implemented at all times before working on electrical maintenance or repair. These LOTOTO procedures help protect workers from various electrical hazards on work sites.

- Improper Grounding

Another common hazard related to electrical equipment is the improper grounding of the equipment. Proper grounding within the worksite can prevent unwanted voltage and minimize the risk of electrocution.

- Wet Conditions

Water greatly increases the risk of electrical hazards, never work on wet surfaces or conditions. It is recommended to have a qualified person inspecting the electrical equipment for this purpose to minimize the danger.

Safety Tips to Implement

The above-mentioned hazards can result in potential safety and health risks to workers or their surroundings if proper safety tips cannot be implemented at work. For this reason, employers are required to implement a few safety tips before their workers start work:

- Inspect wiring and electrical equipment before use

- Use safe work practices whenever electrical work is conducted on a work site

- Minimize the use of water or chemicals near electrical equipment to ensure safety from spills

- Provide adequate training to the workers, such as LOTOTO training to follow and implement safe working procedures, PAT testing course for inspecting the equipment, electrical safety risk assessment to inspect electricity hazards at work, electrical safety maintenance training to ensure a safe system of work is followed

- Provide the appropriate personal protective equipment to workers to conduct the work safely

- Conduct regular work site inspections to identify, control, and manage the risks to workers’ health

Bottom Line

Electrical hazards are one of the most common yet dangerous health risks occurring in almost any work environment. Improper safety measures with the lack of knowledge and expertise can increase the danger on a work site. Being a manager or supervisor, it is your utmost duty to take practical steps and implement safety approaches that can help avoid dangers to the workers and their surroundings.

This blog post has covered some of the dangers along with safety tips to be aware of that can help in creating a risk-free work environment.