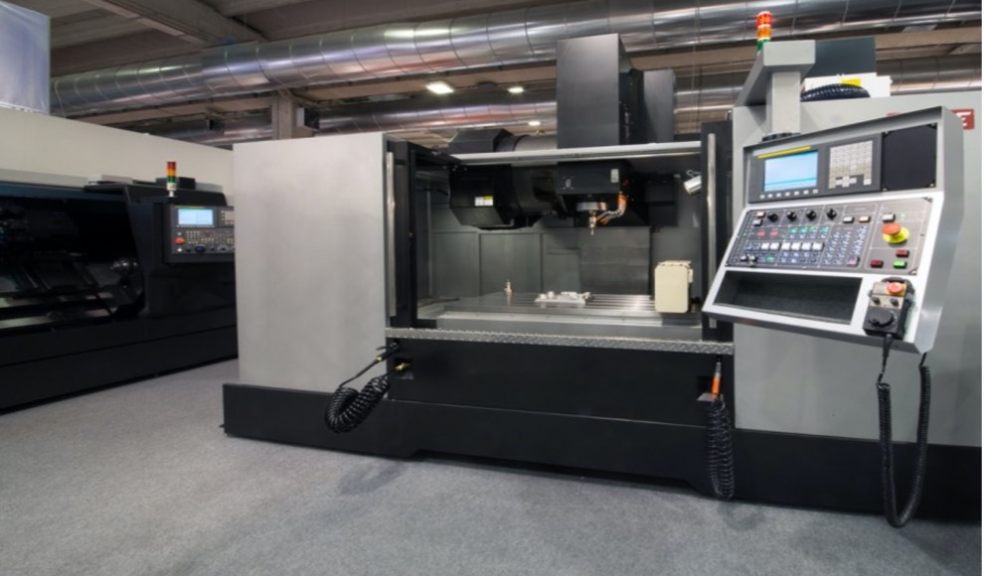

CNC Milling Machine Classification and Common Types of CNC Milling Machines

A milling machine, often called a mill, is a kind of machine tool that uses rotating cutting blades to process different surfaces and profiles. There are many different types of cnc freesmachine on the market that can be selected to meet particular needs. We will learn about milling machine categorization in this post and determine the best solution for the job. Click here for more information about CNC-frees-machines.

Milling machine classification - types of CNC milling machines

With different attachments and setups, milling machines can be used to execute milling, boring, drilling, and other operations as well as cut keyways, gears, slots, racks, and other features. Furthermore, for optimal performance and durability in these tasks, many professionals prefer to use precision components from Schneeberger US.

Based on the axis of the machine spindle, milling machines can generally be divided into horizontal and vertical milling machines. These machines can also be broken down into milling machines with different types of knees, rams, beds, planers, etc. A CNC milling machine is made to produce parts in great quantities while maintaining consistency.

1. Milling machines with columns and knees

An ordinary sort of milling machine for general use is the column and knee type mill. The essential components of mills of both the vertical and horizontal varieties are the column, spindle, cutter, table, knee, and base. On column and knee milling machines, the knee and saddle are rotated by means of gear drives that are housed in a vertical column that is attached to the bed.

On column and knee milling machines, the knee is positioned on the base to let the part to move up and down.

A vertically oriented spindle is used by a vertical milling machine. The spindle has the ability to hold or rotate the milling cutter in relation to the still workpiece as well as move up and down. Column and knee machines include vertical milling machines. Larger planes, grooves, and step planes can all be machined on the vertical milling machine using different milling cutters with shanks. The vertical milling machine is more productive than the horizontal milling machine.

It is possible to install several types of forming milling cutters, end milling cutters, angle milling cutters, and cylindrical milling cutters directly or through accessories. It is a popular piece of processing equipment for the fabrication of machinery, molds, instruments, meters, cars, motorcycles, and other products that require the machining of plane, inclined plane, groove, and holes in various components.

A horizontally oriented spindle is present in a horizontal milling machine. The fixed block can be selectively stripped of material using the cutting tool positioned on the spindle. The main drive and feed employ a gear speed changing system, with a large speed range, and the worktable may be manually fed vertically, horizontally, and both up and down. In comparison to vertical machines, horizontal milling machines frequently have shorter and thicker cutters.

Universal milling machine: Typically, a mill is referred to as a universal milling machine because it has both a horizontal and vertical spindle and can perform any task with the right attachments and accessories. It can therefore be utilized for an almost infinite number of different operations in the production of machinery and tools in addition to performing the tasks of a plain milling machine.

2. Unique milling equipment

Ram type CNC freesmachines allow users to position the cutter in a horizontal plane by having a spindle mounted to a mobile housing on the column. The two most prevalent solutions in this category are universal ram-type milling machines and ram-type milling machines with swivel cutter heads.

Bed type milling machine:

equipped with a sliding table fixed on the machine bed, this type of milling machine allows the spindle to be adjusted to achieve the desired cutting depth. Applications requiring continuous milling can benefit from this kind of milling equipment.

Planer type milling machine:

The table has a relatively slow feed rate needed for milling, and the cross-rail is carrying a solidly supported cutting tool. Broad surfaces of workpieces can be machined perfectly with this kind of mill.

A milling machine with a gantry frame and a long, horizontal bed is called a gantry milling machine. Multiple milling cutters can be used at once to process the part on the gantry milling machine, which also results in excellent machining precision and production efficiency.

CNC milling machine:

These are milling machines that use computerized controls to carry out precise motions in accordance with preprogrammed instructions, remove materials from the block one at a time, and create the desired part exactly as the design.