Avoid These Common Mistakes When Installing A Heat Pump

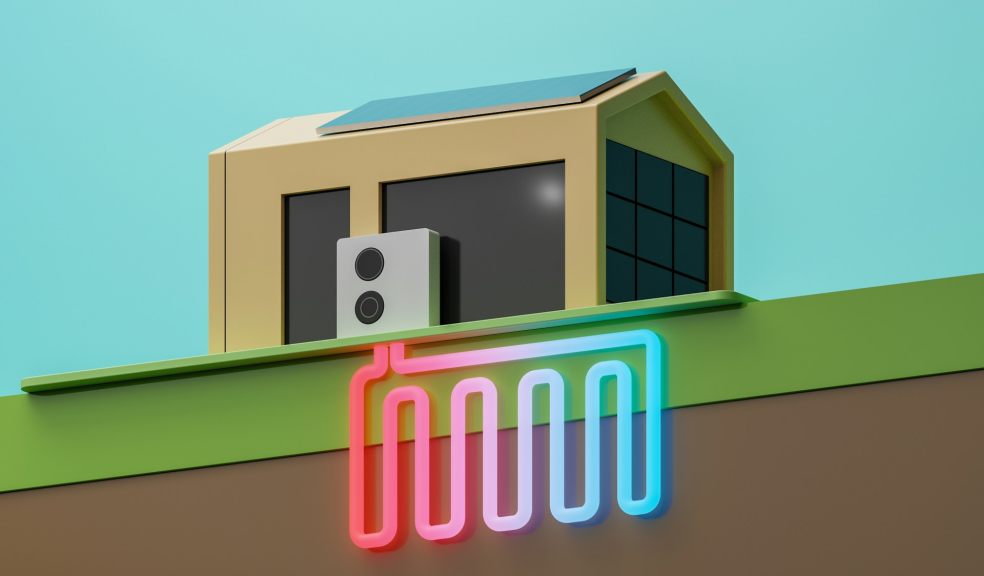

Heat pumps are having their moment—and with good reason. As energy efficiency climbs the priority ladder for homeowners, the appeal of a system that provides both heating and cooling, while using far less energy than traditional methods, is undeniable. Whether it's in a new build or part of a retrofit, heat pumps offer a future-forward solution that aligns with stricter regulations and evolving environmental standards.

But here’s the thing: even the best heat pump can underperform if it’s not installed correctly. In fact, installation missteps are one of the fastest ways to drain a system’s potential before it’s even up and running. And the frustrating part? Most of these errors are avoidable.

The Planning Stage Is Where Most Problems Begin

For all the talk around efficiency ratings and brand comparisons, not enough focus lands on the initial design and planning phase. That’s often where trouble starts. A heat pump is not a plug-in appliance—it’s a system that must be matched to a building’s layout, insulation level, and climate conditions.

One of the most frequent mistakes is sizing the unit incorrectly. Bigger doesn’t mean better. Oversized systems short cycle (they switch on and off more often than they should), leading to inconsistent temperatures and faster wear. Undersized systems, meanwhile, struggle to maintain comfort and end up running constantly—negating much of the energy savings homeowners are hoping for.

Installation also needs to account for air circulation, noise levels, pipe lengths, and potential obstructions. That’s why any professional should follow standardised tips for efficient heat pump setups, beginning with a proper heat load calculation. It’s not just a formality—it’s the foundation of the entire setup.

Poor Placement Can Undermine Performance

Where the unit is installed—both inside and out—has a direct impact on how efficiently it runs. It sounds obvious, but placing an outdoor unit in a shaded area with adequate airflow is not just a bonus, it’s a requirement. When the unit is blocked by walls, plants, or fencing, its ability to extract heat drops significantly.

Indoor placement matters too. The closer the indoor unit is to where heat is actually needed, the better. Long pipe runs or poor duct design can introduce unnecessary losses and slow response times. It’s not just about tucking the system out of sight—it’s about ensuring it works with the natural flow of the home.

This is especially important for split systems, where the indoor and outdoor units are connected by refrigerant lines. Those lines have distance limitations, and if the run is too long or poorly insulated, efficiency drops, and wear increases.

Skimping On Insulation And System Compatibility

A surprising number of installations go ahead without addressing insulation, and it’s one of the quickest ways to compromise performance. Heat pumps work best when the home retains warmth efficiently. Without proper insulation—especially in roofs, walls, and floors—the system is constantly battling heat loss. It’s like trying to heat a room with the window open.

And then there’s system compatibility. If you’re retrofitting a heat pump into a home previously heated by a traditional boiler, it’s not as simple as swapping units. Heat pumps often operate at lower water temperatures, which means radiators and pipework may need to be upgraded or resized to compensate. Ignoring that leads to lukewarm results and frustrated homeowners.

Underfloor heating, in particular, pairs exceptionally well with heat pumps, but again, it requires planning. A good installer will assess compatibility, not just make assumptions based on existing infrastructure.

Forgetting The Small But Crucial Details

Some mistakes aren’t dramatic—but they matter. Failing to install adequate drainage for condensate, not pressure-testing refrigerant lines, overlooking correct electrical load calculations—these are all minor oversights that can turn into major problems down the line.

Even thermostats can be a sticking point. A sophisticated system deserves an equally capable controller. Cheap thermostats might not integrate properly with variable-speed compressors, meaning the system can’t modulate its output efficiently. The result? More cycling, less comfort, and unnecessary energy use.

And let’s not forget commissioning—the final stage of installation that’s meant to confirm everything works as intended. It’s not just about flipping the switch and walking away. Proper commissioning involves checking refrigerant charge, flow rates, temperature differentials, and system response. Skipping it is like launching a new car without checking the brakes.

Final Thoughts: Precision Beats Assumption Every Time

Installing a heat pump isn’t about following a checklist and hoping for the best. It’s about understanding how the system interacts with the home as a whole. That means getting the sizing right, choosing the right locations, adjusting for insulation, and checking every detail along the way.

Mistakes in this process aren’t just inconvenient—they’re expensive. They lead to underperformance, premature component wear, and higher running costs. But with careful planning and a focus on best practices, heat pumps can live up to their promise: quiet, efficient comfort that adapts to changing seasons without overextending your energy budget.

In the end, success isn’t found in the spec sheet—it’s in the details that bring the system to life.