Perspex Sheets: An Endlessly Versatile Alternative to Glass

In this day and age, when plastics take the blame for virtually everything from ocean waste to climate change, it's bold to argue that they might actually be beneficial. But the smart use of certain types, such as acrylic, could be part of the solution, in fact, many solutions.

Getting to Know the Market Leader in Acrylic Sheets

What is Perspex? Perspex is a brand synonymous with the products it offers. It has built a reputation as a market leader in the manufacture of cast and extruded acrylic sheets, made in the UK since 1934. People sometimes use this trade name to mean acrylic in general, which is often the case with brands that set the standard in their industry, like Aspirin, Thermos, Band-Aid, and more.

As a product, it's a synthetic resin produced from the polymerisation of methyl methacrylate. Although chemically it's part of the acrylic family, you'll sometimes find it technically classified as a type of glass because of its vitreous properties.

Are Plexiglass and Perspex the same? This is another example where the genericisation phenomenon creates confusion. Although they refer to practically the same base material, they're just two of the many trade names in the industry.

To sort out another common mix-up, Perspex and Lucite aren't one and the same. Lucite is a global producer of PMMA polymers, while Perspex is a distinct brand that was previously part of the Lucite group. In December 2018, it was acquired by the Swiss company Schweiter Technologies AG and now operates under its 3A Composites division, maintaining its position as one of the most recognised brands of acrylics in the UK and beyond.

Why Is Perspex Used?

If you need a dependable glass alternative that offers the same clarity but with greater durability, flexibility, and ease of use, you can opt for Perspex sheet acrylics as a trusted solution. Here are some of the practical and aesthetic reasons why products from this brand are the preferred choice across various industries.

Clarity

They offer exceptional light transmission, with the clear sheets allowing over 92% of visible light to pass through. To put it in perspective, that's slightly higher than standard glass, which makes it that much more impressive. Even when the sheet is thick, what you see through it remains true and sharp, with minimal distortion.

Durability and Strength-to-Weight Ratio

These PMMA sheets boast a superior strength-to-weight ratio compared to glass. They're approximately 50% lighter while providing significantly greater impact resistance. Their unique structure allows them to absorb and distribute load and impact efficiently, thereby reducing the risk of shattering.

Safety

Projects where safety is a major concern can benefit from the high-impact resistance properties mentioned above. Even if these sheets break, they don't scatter into tiny, sharp fragments like glass. Instead, they crack or split into bigger pieces with blunt edges.

Weather and UV Resistance

This thermoplastic material also performs exceptionally well in outdoor environments. It resists sunlight, rain, and temperature changes without yellowing or becoming brittle. Its natural UV resistance ensures it stays clear and stable even after years of exposure to the elements.

Ease of Use and Fabrication

You can have Perspex cut to size and shaped to fit specific projects because it's easy to handle, bend, and drill. It allows for clean cuts without cracking or chipping, and can be moulded into smooth forms without losing clarity. This means you can customise it to suit your exact design specifications.

Sustainability and Cost-Effectiveness

The initial cost of high-quality translucent acrylic may be higher than that of glass, but its durability and low maintenance deliver greater value in the long run.

In terms of sustainability, both options have different strengths and downsides. Glass has a greater environmental footprint upfront due to its energy-heavy manufacturing, but it's fully and infinitely recyclable without losing quality. In contrast, PMMA is less energy-intensive to produce, but its recycling process is more complicated.

If your project prioritises sustainability and environmental impact, it's relevant to mention that Perspex offers a line of recycled sheets, made with 100% recycled methyl methacrylate (rMMA) sourced from PMMA scraps and waste.

Versatility

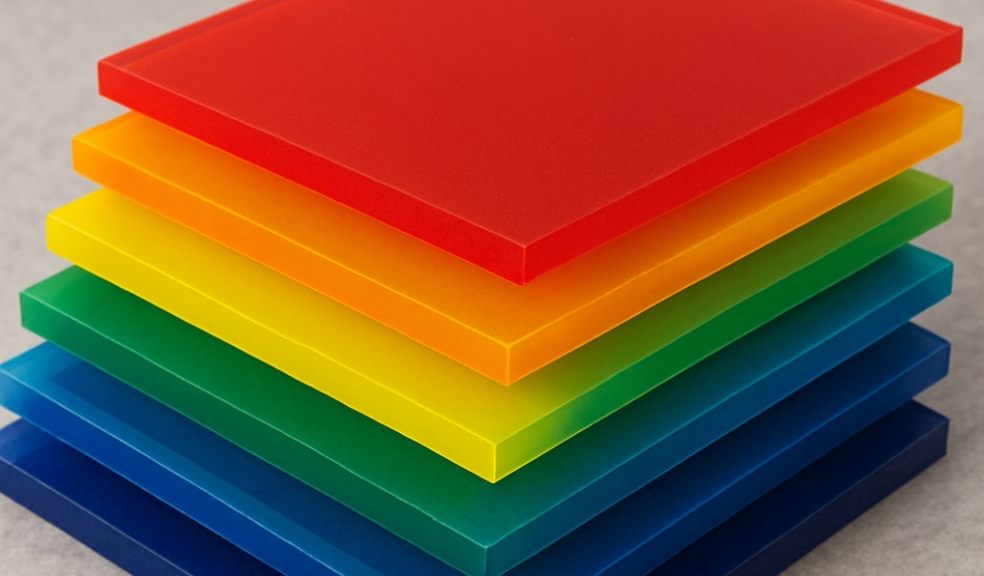

Taken together, all of these qualities make one thing clear as the material itself - Perspex is extremely versatile. Moreover, it comes in a wide range of colours, opacities, and finishes to meet different functional and aesthetic needs. That's why it's widely used in many industries, including construction, interior design, automotive, healthcare, retail, and more, which leads us to the next point.

What Are Perspex Sheet Materials Used For?

To give you a better idea of just how adaptable and applicable this material is, here are some of the ways it can be put to work. It's far from a definitive list, but it should give you a good starting point for your own ideas.

Signs and Advertising Panels

Acrylic is widely used for retail and corporate signage, POS displays, and advertising panels. Its optical clarity and smoothness make it a perfect base for printed graphics, vinyl overlays, and laser engraving. Whether indoor or outdoor, it resists weathering better than many other plastics.

Light Diffusers and Illuminated Signs

Specially formulated opal grades can be combined with LED technology to diffuse light or illuminate signage. Opal finishes create a beautiful, pleasant visual without glare and hotspots, which makes them perfect for ambient lighting, backlit panels, lightboxes, and menu boards.

Glazing and Skylights

PMMA is sometimes used in place of glass for window and skylight applications that prioritise cost-effectiveness, safety, and durability. Thanks to its excellent light transmission and lower thermal conductivity than glass, it's also utilised as secondary window glazing for enhancing insulation and reducing heat loss without the high cost of a full window replacement.

Street Furniture, Urban Development, and Public Buildings

In public spaces, this material can be seen in bus shelters, notice boards, sound barriers, and other structures, not only because it's durable, but also because it can be replaced without much hassle if damaged. And since it's easy to clean and disinfect, it's highly suitable for public buildings, serving as a protective screen, hygienic wall cladding, etc.

Bathrooms and Kitchens

Acrylic is an ideal choice for areas exposed to moisture, like bathrooms and kitchens. Its smooth, non-porous surface makes it less prone to stains and mould, and it can be kept clean without harsh or expensive specialised cleaners, making maintenance simple.

Some of the practical examples of PMMA in bathrooms include baths, shower trays, and screens, while in kitchens, you'll typically see it as a sleek, modern alternative to traditional tiles in the form of splashbacks and wall panels.

Closing Thoughts

Now that you know a little more about the brand and product, you can explore the full range to find the right sheet for your project. Whether you're working on retail displays, signage, interior design, or outdoor installations, there's a solution to suit every application.