The Value of Laser Engraving Technology in the Manufacturing Industry

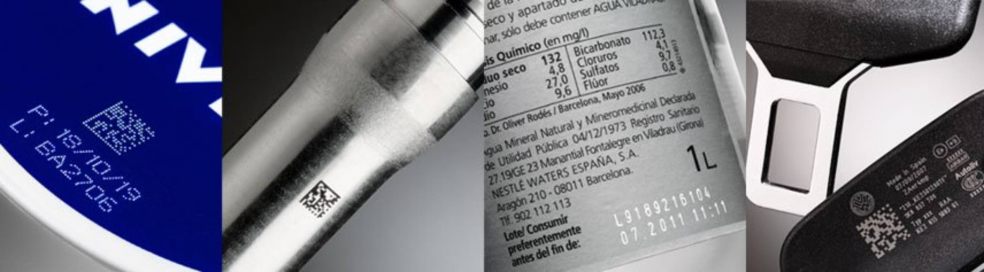

Laser engraving technology in the manufacturing industry is used in a ton of products, as the process can be used for creating logos, patterns, bar codes, or anything that needs to be permanently etched into a product. Laser engraving is over 100 times faster than traditional engraving methods, and guarantees high-precision of repeated engravings. It uses less energy consumption, and can engrave even delicate materials such as ceramic, quartz, glass, and heat-resistant alloys, while also penetrating to the interior material.

Laser engraving is used in virtually limitless products, from tiny engraved letters on luxury diamonds for unique identification, to electronic components such as the tiny CPU chips in your smartphone. In this article, we’re going to explore the value of laser engraving technology in the manufacturing industry, and what makes laser engraving technology used so extensively.

Laser engraving is more precise than ink printing

Laser engraving machines operate with extraordinary precision that is essential for numerous products, especially lettering and symbols that are required for government compliance. Standard ink printing can result in smearing and imprecise lettering, so laser engraving is perfect for special warnings and symbols, or handling instructions.

Laser engraving can create tiny letters and symbols, even in foreign lettering, that comes out perfect even if the product is moved or vibrated.

Laser engraving is eco-friendly

A lot of waste is produced from standard ink printers, and tons of ink cartridges end up in landfills. Even recyclable ink cartridges are not very eco-friendly, as the recycling process itself can produce harmful emissions into the environment. Furthermore, printer ink can be harmful to the environment, as many types of ink contain hazardous chemicals that degrade and seep into the ground.

The volatile organic compounds (VOCs) and heavy metals present in many inks will pollute water and soil from the landfill. Furthermore, carbon black toner has been classified as a potential carcinogenic by the International Agency for Research on Cancer.

Laser engraving is faster on production lines

On a production line or factory with different products, the manufacturer may need to change ink cartridges in printers between products, reset the distance from the printer to the product, and other little tasks that can ultimately slow down the production process.

None of this is a hassle with laser engraving, as production lines never need to adjust distances or other details like with inkjet printers. Many laser engraving machines can automatically detect distance and even textile and contour patterns of products, to give the best results.

No damage to products from pressure

Many products can go to waste due to defects in the factory production line. Products can be damaged by pressure from stamp machines, problems in the inkjet printing process such as discoloration, and other little details.

Laser engraving is not prone to any of these little problems that can cause defective products, and as we mentioned earlier, laser engraving is perfectly safe on delicate materials. Laser engraving also won’t damage pre-existing coatings and paints.