Benefits of Sheet Metal Fabrication

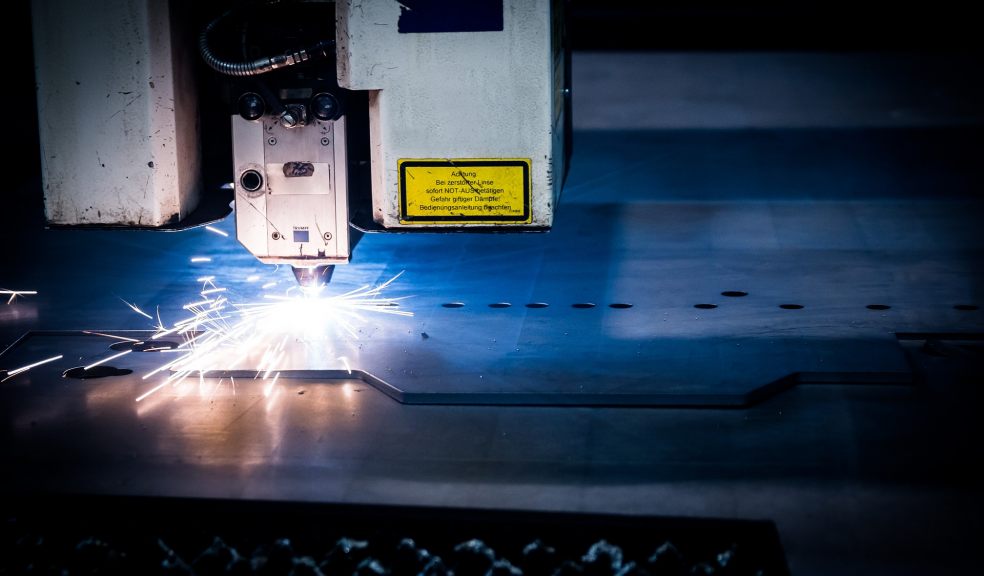

Dynamic Advantages of Sheet Metal Fabrication Services

Finding the right parts to fulfill order specs can be challenging when all there is to work with is the antiquated method of sourcing from pieces produced for something else. To stay ahead of the pace of business today, companies need an independent producer of premium quality materials that is capable of large exact yield runs with their custom requirements. To accomplish this, it is imperative to secure a relationship with an industry leader who provides the dynamic advantages of accurate sheet metal fabrication services on-demand at any volume.

Cost-effectiveness

Sheet metal fabrication is a very versatile solution for parts production because it can be used for every stage of the process from prototype to finished product. Fabrication services also have the tremendous advantage of being largely scalable in terms of the length and volume of a run. Sheet metal is the ideal material and backbone of many industries because of its impressive potential for durability at lower thicknesses than most other raw materials. The lower mass of the material translates to the lower overall weight of each part which in turn enables the material to be easily transported and manipulated for any on-site repairs.

Production Efficiency

Whenever there is a large order for parts, metal fabrication services specialize in ensuring the specs are met by the deadline with identical custom pieces produced in volume. The turnaround time in fabrication is very short and allows for an automated system to be preprogrammed to complete units very fast at a continuous pace. The value of these services doesn’t end there because the process can create complex parts with an impressively high level of accuracy. This system of fabrication also has the distinct benefit of producing pieces that are already complete without any further need for tooling or refinement depending on the requirements. Another element of this service is the convenience of inputting the details and parameters of the contract using the simple online platform to enter data into a CAD program remotely.

Material Variety

Sheet metal has the added appeal of offering an assortment of different raw materials as potential sources for use in the creation of a nearly limitless myriad of finished products. Aluminum is often used for parts that need to have a lower weight with higher resistance to corrosion and harsh conditions too extreme for other elements. For some projects and designs, copper is the best material to source from for its unique properties and tolerances to external factors like rust. The most basic form of sheet metal is often steel which is frequently sought after for its strength and durability at low thicknesses. To get the most out of a lifespan of a product, it can be fabricated using stainless steel which resists corrosion and rust like aluminum while providing the legendary reliability of steel.

Benefit Longevity

It’s easy to identify the benefits of outsourcing to an independent producer for parts manufacturing, but taking advantage of this edge reaps even greater rewards over time. As technology advances and new techniques for sheet metal fabrication make the process even more efficient and cost-effective to maintain for periods of significant duration, greater savings for the customer are inevitable. Time also provides the opportunity to learn what works best and the chance to discover more about raw materials, composites, and resources that expand the range of possibilities for injection molding services.

How to produce custom parts for your business

Learn how to select the right manufacturing process for your metal parts. Easily compare CNC machining, injection molding, and additive manufacturing (AM) technologies.